MUR Blog - Differentials…What’s The Difference? (Pt. 1)

Deconstructed coffees seem to be all the craze these days, but if you’ve been following our posts recently, you would have come across our deconstructed clutch plate limited slip differential. Whilst the former is what keeps us going, the Drexler limited slip differential (LSD) is one of the things that keep our car going.

As always, MUR is pushing to do our best and so in 2015 when we had a little cash to splash, we welcomed the Drexler 2010 Formula SAE (FSAE) limited slip differential model to the family. The Drexler was set to replace the spool used in 2014 and supersede a trusty but tired KAAZ limited slip differential which was also a clutch plate differential.

The Drexler is heavier and mechanically more complex than a spool, and requires regular maintenance as compared to virtually no maintenance in a spool. So, what sort of dynamic edge were we hoping to gain from spending this sort of money and level of compromise? To find out, let’s start from the ground and work our way up.

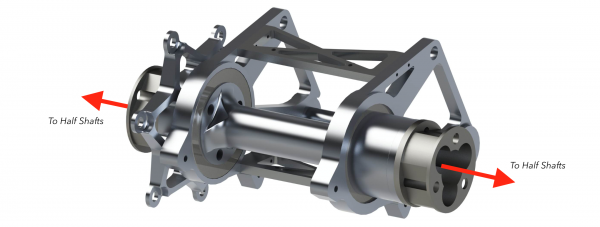

Spool

A spool is a component that essentially couples the two rear wheels such that the wheels are always spinning at the same rate. Commonly found in go-karts and V8 supercars (by regulation), the spool is extremely lightweight and reliable due to its mechanical simplicity. Torque is applied through the tire to the road to push the car forward and is available to both wheels all of the time; albeit distributed unequally. The torque distribution is dependant on the amount of traction of each rear wheel at any given time. Up to 100% of torque can be transmitted through one wheel if the other rear wheel is unloaded.

Further, due to its compact nature, spools make inboard brakes a possibility packaging-wise for FSAE cars. It decreases outboard mass as well as overall weight of the car. Compared to the Drexler which comes in at 2.3kg, the 2014 spool in isolation weighed 0.655kg.

MUR 2014 Spool

2014 Spool with Mounts, Sprocket Carrier and CV Joint Flanges

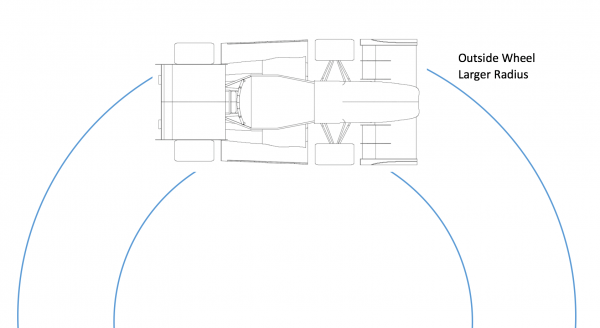

Running a spool however does present some disadvantages; specifically, during cornering. Naturally, when a car turns, the outside wheel traces a longer distance than the inside wheel and so the outside wheel must spin faster. With both wheels coupled to spin at the same rate, a car with a spool will want to fight against the direction of steering since both driven wheels are pushing forward with equal force. This is understeer, where the car turns less than intended. The inner wheel will skip and scuff along the ground because of it.

The Outside Wheel Traces a Larger Distance Than the Inside Wheel

More prominent at low speeds, the effects are slower corner entry, increased power consumption, accelerated tire wear, and greater steering effort – especially for our non-power assisted steering.

One way to tackle understeer in spools is to unload the inside wheel, essentially lifting it off the ground during a turn so that it is no longer scuffing, and letting the outside wheel supply the torque. This can be done by stiffening up the suspension so that when the car leans outwards during a turn, the weight is shifted away from the inside wheel to the outside wheel. The compromise here is less traction during a corner, since there is only one tire contact patch laying down the torque as opposed to having two.

An experienced driver can take the lighter spool set-up and make the car dance, but less experienced drivers may lack the finesse required to unload the inner wheel through corners to counter the understeer.

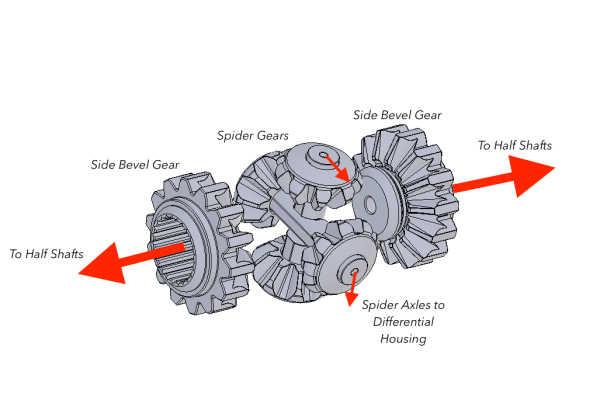

Open Differential

The open differential seeks to alleviate this cornering issue. It makes use of an arrangement of bevel gears to enable differing wheel speeds. In a straight, both wheels will rotate at the same speed, and in a corner, the gearing arrangement enables the wheels to rotate independently of each other whilst still delivering a 50/50 torque split to both wheels, all of the time. The benefit is less understeer enabling faster corner entry and improved drivability. This is why open differentials are commonly found in passenger cars. Not so much for the faster corner entry aspect of course, but for the improved drivability aspect.

Spider and Bevel Side Gear Assembly (CAD Courtesy of Drexler)

I would hazard to say that almost every mechanical engineering student would have gotten one of their most memorable light bulb moments from this vintage General Motors short film explaining the open differential, and if not, have it now:

Around The Corner (1937) How Differential Steering Works

The nostalgia…

But as we were, with the open differential, we encounter the so-called traction difference problem. Consider the following two scenarios. For a spool, the majority of the torque gets transmitted through the wheel that still has traction with the road, allowing the car to be propelled forward. For the open differential case however, the power flows through the path of least resistance, causing the wheel to slip and spin on the spot with high rpm but low torque.

Slippery road surfaces, a lightly loaded wheel or even an engine with sufficient power to overcome the traction limit of the tires will cause a loss of traction and the power to ‘escape’ through the wheel with the least resistance, resulting in wheel slip. There is still a 50/50 torque split between the two wheels despite spinning at different rates, but the wheel with traction will only get as much torque as the slipping wheel, which is very little; hence, the car is not pushed forward whilst wheel slip is experienced to the detriment of lap times. Such occurrences are uncommon enough for passenger cars, but in racing it just won’t cut it.

A spool is good for supplying torque to the ground without caring about which wheel has the most traction, but is characterised by heavy understeer. An open differential, on the other hand, allows the two wheels to spin at different speeds thus mitigating understeer, but will send the majority of the power to the slipping wheel the moment a wheel loses traction. If only there was some happy medium which would allow two wheels to spin at different speeds but also send torque to the wheel with the most traction if slipping ever occurs…

Enter the limited slip differential.

Drexler FSAE 2010 Limited Slip Differential

This post is part one of a two-part series. Click here to read part two.

Want to hear more from us? Sign up here and never miss a post! No spam, promise.

About the Author:

Brendan Giang

Lead Brakes & Drivetrain Engineer, 2017

Junior Brakes & Drivetrain Engineer, 2016

Junior Brakes & Drivetrain Engineer, 2015